Thermal Energy Receives First Order for its New Hybrid Flu-Ace

The combined Flu-Ace heat recovery unit and Perco-Ace direct fired water heater is expected to reduce the customer’s fuel use for hot water by 80%

Record Custom Equipment orders and revenue and record Turn-key Project development indicate strong, growing demand from customers.

OTTAWA, ONTARIO – April 29, 2022 – Thermal Energy International Inc. (“Thermal Energy” or the “Company”) (TSX-V: TMG, OTCQB: TMGEF), an innovative cleantech company and global provider of proprietary energy and carbon emissions reduction solutions to some of the world’s largest corporations, has announced its financial results for the third quarter ended February 28, 2022. All figures are in Canadian dollars.

Third quarter highlights:Overview

“These disappointing quarterly results reflect the continued ongoing disruptions caused by the global pandemic. Over the last two years, we have made conscious strategic decisions to keep investing in the capabilities and future growth of the Company. We did this because we believe, that emerging from the pandemic there will be an unprecedented market opportunity for growth, and we want to make sure we are in as strong a position as possible to capitalize on this opportunity. But clearly, the COVID-19 pandemic is presenting longer-lasting and much more nuanced impacts than anticipated. For much of the last two years, our customers and suppliers have endured reduced workforces, restricted travel and site access, and growing supply chain issues. Given this, many of our customers, often working with ‘skeleton staff’, have been focusing on continued operations rather than new projects, growth, or development. While our Custom Equipment revenue has continued to grow, these pandemic-related issues have resulted in delayed and protracted Turn-key Project development and delivery, and this is having a significant impact on our recent revenue and results. In addition, recent labour and material shortages and inflation are also having a negative impact on our costs and margins. While we have already begun implementing price increases to reflect this new reality, this will take some time to filter through” said Thermal Energy CEO, William Crossland.

“Nonetheless, despite the recent results, we believe the Company’s capabilities, and the market fundamentals, are aligning for an even more significant opportunity than originally anticipated. Given our customers’ increasing carbon emission targets and sky-rocketing energy costs, we are seeing unprecedented customer interest and engagement. Custom Equipment order intake and revenue, continue to set records and are already significantly higher than pre-pandemic levels. While Turn-key Project revenue has not yet caught up, we currently have 17 Turn-key Projects in paid development. While not all of these projects may come to fruition, this level of project development is more than double the Company’s pre-pandemic high. Consequently, we maintain confidence in the viability of our solutions to answer the market needs and remain encouraged by the current market opportunities. We believe that we can deliver the growing sales pipeline and capitalize on the current favourable market conditions.” said Thermal Energy CEO, William Crossland.

Custom Equipment vs. Turn-Key Projects

Thermal Energy sells its energy efficiency and carbon reduction solutions as either a customized piece of equipment or a fully installed turn-key project. Pre-pandemic, Turn-key Projects represented about two-thirds of revenue with Custom Equipment (primarily GEM and Heatsponge) one-third. But more recently, with strong growth in Custom Equipment, Custom Equipment revenue has exceeded Turn-key Projects.

While Custom Equipment projects must still be engineered and installed at the jobsite, these equipment-only sales are much less complex and much less expensive than our Turn-key Projects. Given the human resource and capital commitment required from the customer, not to mention the detailed engineering, regular site visits and ultimate turn-key installation, our Turn-key Project business tends to have a much longer development, sale, and revenue cycle. The fact that we have been experiencing significant growth in Custom Equipment demonstrates strong demand in post-pandemic markets for thermal energy efficiency solutions and as would be expected is happening first in lower cost and easier to manage Custom Equipment segment. As our large corporate clients begin to return to pre-pandemic business cycles we anticipate Turn-key Projects will rapidly follow.

Custom Equipment

Custom Equipment order intake and revenue continue to be at record levels, approximately 39% and 23% respectively ahead of pre-pandemic levels.

The performance of our Custom Equipment business is extremely positive despite some challenges. Global supply chains have witnessed notable disruption. We have experienced difficulties and extraordinary delays sourcing some key materials and parts which has led to the delay in shipping a significant number of Custom Equipment units. Our work in progress and order backlog over the last two quarters is the highest it has ever been and has therefore temporarily impacted revenue recognition for our Custom Equipment segment.

The supply chain disruption goes beyond raw materials, extending to labour shortages due to sickness and quarantining requirements as well as general employment levels. The ‘Great Resignation’ has sent shockwaves through the labour market affecting the supply chain. These problems are significant, and they are global. To protect and strengthen our supply chain, we are developing alternative and secondary suppliers in line with our quality systems, and fully utilising our U.S. based facility to increase bulk purchases and increased stock holdings to better respond to supply issues.

Despite these challenges, record order and revenue levels for Custom Equipment are consistently being achieved.

Turn-key Solutions

Turn-key Project development is at record levels.

In parallel to Custom Equipment, Thermal Energy also develops and delivers unique and innovative turn-key carbon emissions reduction and sustainable thermal energy solutions for its customers. These Turn-key Projects[3] are developed in partnership with the customer often with the implementation of a paid Project Development Agreement (“PDA’).

In the Last Twelve Months (LTM) ended February 28, 2022, Thermal Energy received 10 new PDA orders and currently has 17 Turn-key Projects in paid development with customers. Both of these figures are at least twice the Company’s pre-pandemic highs and easily the highest level of Turn-key Project development in its history.

A paid PDA is the customer’s commitment to a project whereby, based on an initial estimate of project cost and savings, the customer agrees to front the cost of further project development engineering before a final decision is made to execute the project.

Turn-key Projects already in progress during the pandemic have taken longer to complete and for revenue to be realized, mainly due to travel and site access restrictions, and covid isolation and sickness of our customers’ staff. Suppliers on these projects are often highly integrated into the project delivery and they have faced similar problems with staffing as well as with the manufacture and supply of essential equipment. In summary, regular holdups have created an inefficient staccato delivery and a ‘long tail’ on our Turn-key Project delivery that we did not anticipate after restrictions eased.

While the easing of COVID restrictions allowed for some normalcy, we did not envision that our large multinational clients and key suppliers would continue operating on skeleton staffing and prioritising essential operations due to the limited workforce, for as long as they did. Challenges accessing the whole project team at once, even when restrictions are eased, has meant a reduction in normal progression. Our teams have faced challenges in progressing the development of projects in our pipeline. Throughout our development pipeline, momentum of communications with key people and the ability to gain the necessary site access have meant project development and closure have slowed whilst our teams wait for travel restrictions and isolation periods to end as they manage protracted sales cycles. Highly qualified pipeline projects with well recognised financial benefits have also in some cases been affected simply by a delay in natural budgetary cycles.

“The record PDA levels can be seen as a positive indication of future Turn-key Project order intake levels. Other areas of the Turn-key Project pipeline however have been impacted since the onset of the pandemic and this is reflected in the financial results. Although the disruptions are expected to continue in the short term, the reasons for disruptions are known, understood and are being managed, and we believe order intake will bounce back due to the continued viability of our solutions to quickly and dependably achieve customers carbon reduction targets and significantly impact their ability to manage volatile energy prices.” said Thermal Energy CEO, William Crossland.

Positive Market Fundamentals

It’s clear that the disruption of covid has lasted longer than anyone expected and longer than simply the government-imposed lockdowns and restrictions. Although we cannot predict how long our customers and suppliers will have to manage these staffing and operations challenges, the requirement to reach net-zero and reduce carbon emissions persists and is influenced further by the extremely volatile and increasing energy prices.

As reported in the last quarter, North American and EU natural gas prices have significantly increased (between 100% and 500%) in the last 12 to 24 months. There has also been a rising demand for carbon allowances under the EU’s cap-and-trade system. EU Carbon Permits reached an all-time high of more than 90 EUR in February 2022, and continue to trade in the 80 – 90 EUR range, 100% to 300% higher than they were 12 to 24 months ago. Meanwhile, Canadian Carbon Taxes are now $50/t and are expected to reach $170/t by 2030.

As our customers seek to establish a ‘new normal’, they also reconsider and refocus their priorities. In the face of staffing crises, operational restrictions, increasing energy prices and emissions targets, any move to cut operational costs is more advantageous than it has ever been. Since Thermal Energy provide an immediate and easy route for multinational manufacturers to achieve the required savings, these factors only increase the economic attractiveness and short-term paybacks to our customers.

“The mounting pressure on our customers is multifaceted, to respond to consumer and Government pressures to reduce emissions, whilst achieving operational effectiveness amid energy cost increases and workforce disruptions. This refocusing of priorities benefits Thermal Energy since longer paybacks are being considered, allowing previously considered pipeline opportunities to be revisited,” said William Crossland.

With approximately 50% of industrial thermal energy lost on-site due to inefficiency, energy efficiency is the fastest, cheapest, and most significant way to reduce carbon emissions, and the market opportunity for Thermal Energy is significant and growing.

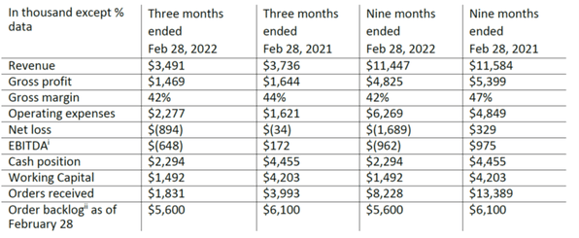

Summary Financial Results

The combined Flu-Ace heat recovery unit and Perco-Ace direct fired water heater is expected to reduce the customer’s fuel use for hot water by 80%

Fiscal 2024 was a record year for revenue, order intake, and EBITDA

Company reports results for fourth quarter and fiscal year 2025; record order intake for first quarter of fiscal 2026

Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of today’s industry.